Republished with permission of Momentum,

Republished with permission of Momentum,

a School of Engineering electronic publication.

In January, Mark P. Vergnano (B.S. Chemical Engineering, ‘80), Executive Vice President of DuPont, was named to become Chief Executive Officer of DuPont’s $8 billion Performance Chemicals segment, which will be spun off during the second quarter of 2015 as a stand-alone company. It is just the latest in a long series of laurels for Vergnano, whose 33 year career with DuPont has spanned top executive positions in seven of the company’s units across two continents.

As Executive Vice President, Vergnano has had responsibility for about half of DuPont’s total businesses, including Performance Chemicals, Electronics & Communications, and Safety & Protection along with oversight of sales/marketing/communications and safety/sustainability. When the new Performance Chemicals company is launched, he notes, “It will be the 12th or 13th largest chemical company in the world. The Titanium Technologies and Chemicals & Fluoroproducts units that make up Performance Chemicals are both global leaders in their industries, so we will be in a very good position from the start.”

He explains that the major products within Titanium Technologies are whiteners or opacifiers used in a wide range of applications, from toothpaste to paint to plastics. The company’s Chemicals & Fluoroproducts business produces scores of specialty products, including disinfectants, refrigerants for stationary and mobile air conditioning, non-stick Teflon® coatings for pans, and unique industrial polymers used in automobiles, solar energy and electronics.

As Vergnano prepares the Performance Chemicals company for its debut as an independent entity, he notes, the company “Will continue to differentiate itself from competitors by working hand in hand on developing applications with our key customers, which include companies such as Gore, known for its top-selling Gore-tex™ brand of products. With another large customer, Sherwin-Williams, we are working to develop paints that provide one-application full coverage and also have great cleaning capacity, thanks to our unique titanium dioxide opacifiers. Batteries are a new market for us as electric vehicles grow more popular. EVs require batteries that can operate at a higher temperature and for longer durations than they have ever had to before. By using fluorochemical based electrolytes, these batteries can operate in higher temperature conditions for longer periods of time resulting in longer charges. We are also in the midst of introducing our next generation of sustainable mobile refrigerents, Opteum® YF, which has the lowest global warming potential of any refrigerant in the industry.”

He remarks, “As a separate company, we will have the ability to be more flexible and nimbler than DuPont, giving us the freedom to make investment decisions that might not have been a priority within the DuPont structure. We will be a strong cash-generating company with a goal to deliver cash back to our shareholders in the form of strong dividends and returns.”

Storied Career

Vergnano’s UConn chemical engineering education honed his analytical acumen and helped him succeed in a career blending engineering and business leadership. “I believe that an engineering background gave me the advantage to solve problems in a very logical and disciplined way,” he remarks.

During his decorated career with DuPont, he has been involved in many exciting developments. Two in particular stand out. “Early in my career, during the 1980s, I was a member of a very small team that developed Tyvek™ Homewrap®. At that time, the product had about $2 million in sales. Traditionally, builders applied insulation and maybe a sheathing board on top of that. We built the business almost from the ground up. We would go out and talk with architects and builders and convince them of the advantages of our Tyvek® wrap. Today, it’s the standard in building construction because Tyvek® Homewrap saves homeowners money on their heating and cooling bills, reduces water damage, and extends the durability of home construction. Today, sales of Tyvek® Homewrap approach a quarter of a billion dollars.”

Another point of pride for Vergnano is more recent. “About three years ago I was asked to lead an effort to reposition the company from that of a traditional chemical company to a science company. We developed a position called, ‘Welcome to the Global Collaboratory,’ which reflects DuPont’s commitment to bringing our science together with different stakeholders from the private and public sectors to help solve global problems like food, energy and protection. Using that positioning as a basis, we have revamped the company over the last three years through innovation, acquisition and divestitures. The success of our new positioning is apparent when we recruit on college campuses and describe our work: it’s rewarding to watch students’ faces light up and to see their excitement when we talk about a company that is truly making the world a better, safer, healthier place for people to live in.”

Vergnano has risen through the ranks of engineering and top administrative posts at DuPont, which he joined soon after earning his B.S. at UConn, as a process engineer in the former Fibers Department in Richmond, Virginia. There, he was involved in manufacturing and technical assignments for the Kevlar® and Tyvek™ products while also earning his MBA through an executive program offered by Virginia Commonwealth University. Over the next decade, Vergnano and his wife, UConn alumna Betsy (formerly Elizabeth Reddington, CLAS ‘81), relocated to Wilmington, Delaware and subsequently to Geneva, Switzerland, where he served as marketing manager for Typar® carpet backings.

In 1993, he was appointed European Regional Business Manager at DuPont Nonwovens, and in 1996 the Vergnanos relocated again to Richmond, where he assumed the role of Global Business Manager for the Teflon® fiber business. He became Global Business Director for the Nomex® business in October 1998 and then was appointed Global Business Director for Tyvek™/Typar® in March 2001, relocating once more to Wilmington. He served as Vice President and General Manager of DuPont Nonwovens from 2003-05, Vice President and General Manager of DuPont Building Innovations from 2005-06 and Group Vice President of DuPont Safety & Protection from 2006-09. Outside of DuPont, Mark is the proud father of his two adult daughters, Elise and Haley, who are living and working in Boston and New York, respectively.

UConn Years

Vergnano loved his UConn years. “The School of Engineering is not huge, and the Chemical Engineering Department in particular is not very big. But that is the basis for some of my fondest memories. I knew my classmates well, because it was the same 20 to 30 people in all of my engineering courses. In fact, I am still very close with two former classmates, Ray Gansley and Chris Siemer. We have stayed in touch since graduation and make a point of seeing each other at least once a year. Because UConn is a public university, we had the opportunity to take courses outside of engineering and to explore other disciplines. UConn offers a well-rounded environment. It also holds the dearest memory for me, since it is where I met my wife, Betsy. ”

His advice to engineering students? “I think engineering is a fantastic discipline,” he says. “It’s not an endpoint, but rather a great background that will serve you throughout your career. Don’t think of engineering as merely a discipline. I’ve been in manufacturing, sales, marketing, R&D, and business leadership…I always fall back on my engineering training, which is rooted in logic, analysis, and problem solving. It’s a tremendous field, and today we need engineers more than ever.”

Vergnano, who was inducted into UConn’s Academy of Distinguished Engineers in 2005, serves on the Board of, Johnson Controls, Inc. and the U.S. National Safety Council; and is a member of the Advisory Boards for the UConn School of Engineering and the University of Delaware Lerner College of Business and Economics. The Vergnanos are committed to making a college education affordable for dedicated students through their Vergnano/Reddington Family Scholarship Fund at UConn.

Vergnano will deliver the keynote presentation at the 2014 AIChE Northeast Regional Student Conference in Storrs on April 5th, during the conference banquet.

In 2003, researchers realized that green algae respond to high intensities of light using ion channels that sense blue light. The light-activated channels allow ions to flow through the cell membrane, resulting in the initiation of electrical signals called action potentials in neurons. This finding signifies that light energy can be used to trigger electric signals in specific populations of neurons.

In 2003, researchers realized that green algae respond to high intensities of light using ion channels that sense blue light. The light-activated channels allow ions to flow through the cell membrane, resulting in the initiation of electrical signals called action potentials in neurons. This finding signifies that light energy can be used to trigger electric signals in specific populations of neurons.

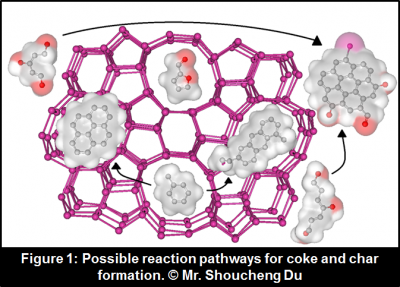

Mr. Shoucheng Du, Prof. Julia Valla, and Prof. George Bollas are making exciting progress in developing the process of biomass catalytic pyrolysis. Their recent achievements are published in Green Chemistry (

Mr. Shoucheng Du, Prof. Julia Valla, and Prof. George Bollas are making exciting progress in developing the process of biomass catalytic pyrolysis. Their recent achievements are published in Green Chemistry (

The Research Experience for Undergraduates (REU) program provides undergraduates with exposure to a stimulating research environment.

The Research Experience for Undergraduates (REU) program provides undergraduates with exposure to a stimulating research environment.

The chemical engineering graduate program at the University of Connecticut is comprised of bright, innovative leaders who are motivated by change and challenge. The program offers the opportunity for students to enhance their skills and develop their potential.

The chemical engineering graduate program at the University of Connecticut is comprised of bright, innovative leaders who are motivated by change and challenge. The program offers the opportunity for students to enhance their skills and develop their potential.

Dr. Nieh was recently awarded a National Science Foundation grant in 2012 to design such nano-carriers. “Lipid-based nanodiscs and vesicles have the potential to serve as delivery carriers for therapeutics or diagnostic agents, so the stability of the structure is an important issue,” he said.

Dr. Nieh was recently awarded a National Science Foundation grant in 2012 to design such nano-carriers. “Lipid-based nanodiscs and vesicles have the potential to serve as delivery carriers for therapeutics or diagnostic agents, so the stability of the structure is an important issue,” he said.

Dr.

Dr.